There are many options to choose from when it comes to insulation to house energy saving.

Two popular choices are spray foam insulation and fiberglass. Both have their own set of benefits and drawbacks, so it’s important to weigh the pros and cons before making a decision.

In this article, we have given complete explanations about these two types of insulation and we have also compared them from different aspects.

What is Spray Foam Insulation?

Spray foam is a material that is applied in liquid form and then formed into foam. It is commonly used in residential and commercial buildings to create an air-tight seal, providing excellent thermal insulation, house energy saving and reducing energy costs. Spray foam can be applied to various surfaces, such as walls, ceilings, and floors, and it effectively fills gaps and cracks to prevent air leakage.

What is Fiberglass Insulation?

Fiberglass also known as glass wool, is a type of thermal insulation material made from a glass that is melted down and spun into long fibers. It is commonly used in residential and commercial buildings to help regulate temperature and house energy saving. It is known for its cost-effectiveness, fire resistance, and ability to resist mold and moisture.

Comparison of Installation Processes

Spray Foam Insulation Installation Process

The spray foam is applied using a special spraying machine. The foam is sprayed onto the surface in a thick, even layer, filling in cracks, gaps, and crevices to create a seamless barrier against air and moisture infiltration.

As the spray foam is applied, it expands to fill the area completely, creating a tight seal that helps to improve energy efficiency and reduce heating and cooling costs.

After the spray foam is applied, it needs time to cure and harden. This process usually takes several hours.

Once the spray foam has cured, any excess foam that may have expanded beyond the desired area is trimmed away using a special cutting tool to create a clean, finished look.

Overall, the spray foam insulation installation process is a relatively quick and straightforward process that can be completed in a matter of hours, depending on the size and complexity of the area being insulated. It is important to hire a professional contractor to ensure that the spray foam is applied correctly and effectively to maximize its house energy saving benefits.

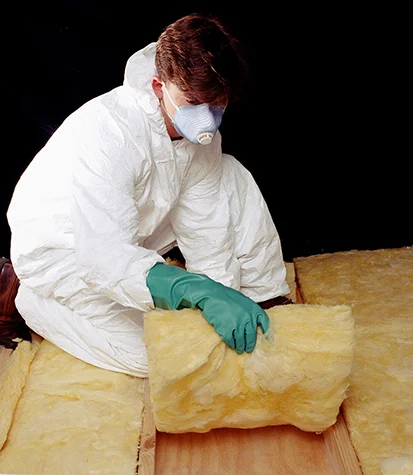

Fiberglass Insulation Installation Process

The contractor will assess the specific needs of your home or building, including the type of insulation required, the *R-value needed for energy efficiency, and the areas that need to be insulated.

The space where the insulation is installed is measured and the sticks or rolls of fiberglass are cut according to the dimensions of the area.

They place the cut insulation in the desired space and ensure a comfortable fit.

They use staples, supports or other fasteners to secure them and prevent it from sagging or falling.

To prevent air leakage, sealant or foam sealant is used to seal any gaps or cracks around doors, windows, pipes and electrical outlets.

The time it takes to install fiberglass can vary depending on the size of the area being insulated and the experience of the installer. On average, it can take anywhere from a few hours to a full day to install fiberglass in a typical home.

In comparison, spray foam typically takes less time to install than fiberglass . This process can be completed in a fraction of the time it takes to install fiberglass.

However, spray foam is generally more expensive than fiberglass , so the choice between the two will depend on factors such as budget, energy efficiency goals, and the specific needs of the space being insulated.

* The R-value is a number that indicates how well a material resists the flow of heat. If it resists heat flow well (high R-value), it is a good insulator.

Comparison of Energy Efficiency and Cost

Fiberglass is generally more affordable than spray foam , making it a popular choice for budget-conscious homeowners.

Fiberglass is effective at reducing heat transfer and improving energy efficiency in homes. However, it can settle over time and lose some of its insulating properties.

Spray foam typically provides higher house energy savings compared to fiberglass . This is because spray foam creates a more airtight seal, preventing air leakage and reducing heat transfer. This can reduce heating and cooling costs over time.

In terms of cost savings, spray foam may have a higher upfront cost compared to fiberglass . However, the long-term energy savings from spray foam insulation can often offset this initial investment. Additionally, spray foam is known to have a longer lifespan than fiberglass , reducing the need for replacement and maintenance costs in the future.

Overall, while spray foam may have a higher initial cost, it can provide greater house energy savings and cost benefits in the long run compared to fiberglass .

Comparison of Environmental Impact and Health Considerations

Fiberglass is a good choice for the environment because it is made from recycled glass and sand. However, the production process of fiberglass does require a significant amount of energy, which can contribute to greenhouse gas emissions. Fiberglass can also release small fibers into the air when disturbed, which can be harmful if inhaled.

Spray foam, on the other hand, is made from chemicals that can have a higher environmental impact. The blowing agents used in spray foam can be potent greenhouse gasses, contributing to climate change. Additionally, some spray foam products contain harmful chemicals such as isocyanates, which can off-gas and cause respiratory issues if not properly installed.

In terms of health considerations, fiberglass can irritate the skin, eyes, and respiratory system if not handled properly. It can also release small fibers into the air, which can be harmful if inhaled. Spray foam can also release harmful chemicals if not installed correctly, leading to respiratory issues and other health concerns.

Generally, both have their own environmental impacts and health considerations. It is important to weigh the pros and cons of each and choose the option that best suits your needs and priorities.

Comparison of Durability and Maintenance

fiberglass is known for its durability, as it can last for several decades without losing its effectiveness. However, over time it can settle and lose some of its insulating properties. Maintenance for fiberglass typically involves checking for gaps or tears in the material and replacing it if necessary.

On the other hand, spray foam is also durable and can last for a long time without needing to be replaced. It forms a tight seal when applied, which helps prevent air leakage and moisture intrusion. Maintenance for spray foam usually involves inspecting for any cracks or damage and reapplying foam if needed.

Both have their advantages in terms of durability and maintenance. However, spray foam may be considered better in terms of maintenance as it forms a more effective seal and is less likely to settle over time. Ultimately, the choice between the two will depend on factors such as budget, and personal preferences.

Conclusion

Spray foam can be applied to many surfaces, effectively filling gaps and cracks, providing excellent thermal insulation and reducing energy costs compared to fiberglass. Offers more energy savings. It generally has a higher initial cost but can provide more energy savings in the long run.

Fiberglass is made from recycled glasses and sand, which makes it relatively environmentally friendly. It is effective in reducing heat transfer and improving energy efficiency, but it can settle over time and some insulation properties to lose but Generally more cost effective than spray foam.

As a result For budget-conscious homeowners looking for a cost-effective option, fiberglass may be a suitable choice.

For those prioritizing energy efficiency and long-term savings, spray foam could be the better option.

Ultimately, the choice between spray foam and fiberglass will depend on factors such as budget, energy efficiency goals, and personal preferences.

To achieve house energy savings, it is essential to start with a thorough home energy audit. This comprehensive assessment allows you to identify areas where energy is being wasted and provides valuable insights into potential efficiency improvements. By conducting a home energy audit, you can pinpoint specific areas for improvement, such as insulation, air leaks, and inefficient appliances.

To schedule a professional energy audit for your home click here.

Taking this proactive step towards energy efficiency can lead to significant cost savings and a more sustainable living environment for you and your family.